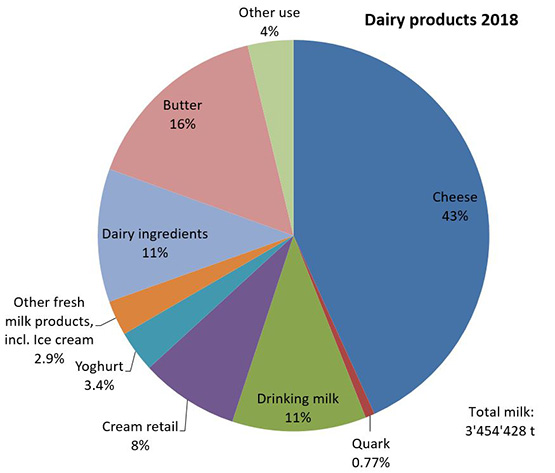

Approximately 10% of Swiss milk is used directly to manufacture dried-milk products and condensed milk (long-life dairy products). The figure fluctuates between around 8% and 13%, depending on the market situation of milk and dairy products. In 2015, for example, the amount of products containing dried-milk products and condensed milk came to 50,500 tonnes, manufactured from 358,000 tonnes of milk (10.3% of total milk production). Included in this but not listed separately are novel milk proteins, lactose, and other dairy components obtained from skimmed milk, whey or buttermilk. In addition to the quantity of milk for long-life dairy products shown in the statistics of the TSM (=Treuhandstelle Milch GmbH), concentrates and dried-milk products are also manufactured e.g. from skimmed milk, from buttermilk from butter production, and from around 55% of the whey from cheese production.

The range of milk-based food ingredients is wide, and their uses are varied. Skimmed- and whole-milk powder is exported to countries with milk shortages. Powdered whole milk is an important ingredient in Swiss chocolate. Particularly high-quality special protein powders are used for nutraceuticals, sports nutrition, or as a natural emulsifier. A complete food substitute for infants consists of various dried products from milk, such as skimmed-milk powder, whey-protein concentrate, α-lactalbumin, lactose, and in some cases special protein fractions such as lactoferrin. Additional ingredients are used here.

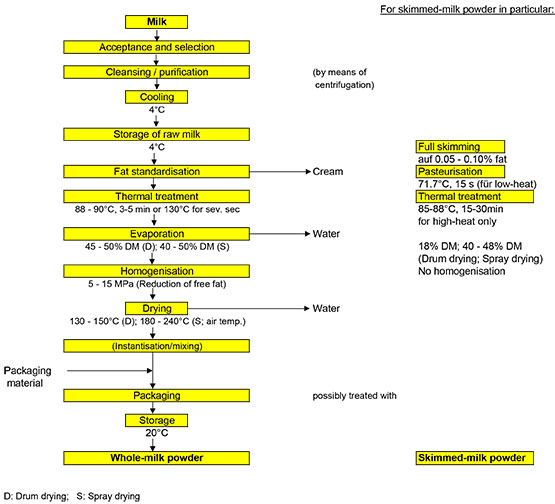

Depending on the product in question, all milk components are either concentrated via dehydration (whole-milk powder), or individual components such as casein, whey proteins and other high-quality components are selectively separated and concentrated via gentle, innovative membrane separation techniques and further separating processes. In concentrated or powdered form, these products have a long storage life, thanks to their low water content.