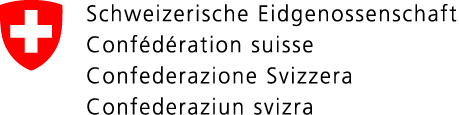

The first stage of butter production consists in breaking the oil-in-water (O/W) emulsion of the buttermaking cream and agglomerating the freed milkfat into butter grains (cf. figure). The butter grains are then kneaded intensively in order to obtain a water-in-oil (W/O) emulsion that is as finely dispersed as possible. Water-droplet size should not exceed 10 micrometres, so that bacterial growth in the butter can be kept low. Should a so-called structural breakdown occur, i.e. should small water droplets coalesce into large drops, a high risk of spoilage ensues. Proper process management is therefore of great importance.

Butter Production

Breaking of the cream emulsion and hence the formation of butter grains occurs at a temperature of 10-15° C. The temperature is chosen so as to yield a ratio of 1:1 for the solid and liquid phases of the milk fat, which enables good butter-grain formation.

To prevent subsequent hardening, the butter must not warm significantly during either the buttermaking stage or subsequent processing. New studies show that the use of chilled kneaders is actually worthwhile, so that the butter can be packaged at a temperature of 11°C or lower. In many cases, butter is even kept in interim storage for several days at 2–3°C before packaging. The stored butter is then reprocessed in butter homogenisers and kneaders (twin-screw extruders). Some of these techniques have become so sophisticated that physical cream ripening can be omitted with no loss of spreadability.

Buttermaking Methods

Various processes are used in buttermaking.

The most common ones are the following:

- Batch process (butter churn):

The buttermaking cream is churned for 30–45 minutes with the incorporation of air at 20–30 min-1 until butter grains form and the buttermilk separates. The butter grains are usually washed with water. Afterwards, the mixture is kneaded until the butter is as homogeneous as possible and the remaining buttermilk is distributed in fine droplets of liquid in the fat phase.

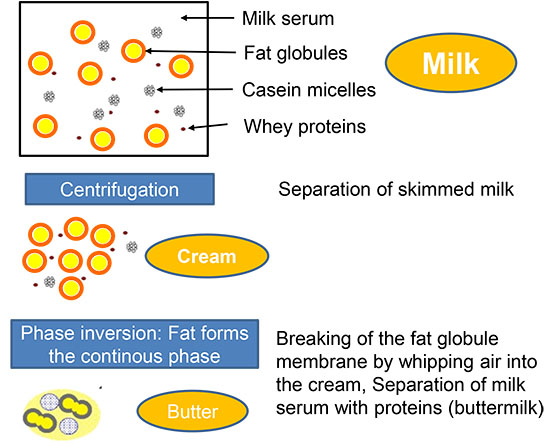

- Continuous butter-churning machine:

The cream, is continuously pumped in, and churned with rapidly rotating (500-3000 min-1) beaters (cf. figure). The cream emulsion is broken after around 30 seconds, forming butter grains and buttermilk. The majority of the buttermilk drains off, while the remainder is worked into the butter. The butter is then kneaded in several stages until homogeneous. Depending on the type of butter, a salt solution or lactic-acid and flavour concentrates can be added and incorporated before a final processing. The latter process is part of the so-called NIZO process, used to produce acidified butter from sweet cream.

| Top cylinder: | Butter-making | Product and media flow: |

|---|---|---|

| Middle cylinder: | Post-churning and pre-kneading | Yelow: Cream - butter Blue: Buttermilk |

| Transition, middle-bottom cylinder: | Addition of lactic-acid concentrate and flavour concentrate | Green: Ice water |

| Bottom cylinder: | Kneading station |

|

Alfa method:

- Cream is adjusted to the desired fat content of the butter to be produced – generally 82% – and heated. Phase reversal is initiated by shock cooling in scrape chillers. The buttermaking process is completed with pinworkers and resting tubes. Reduced-calorie butter products, butter preparations and reconstituted products are frequently produced in so-called combinator systems (Alfa process). To produce reconstituted butter, the Alfa process is generally used after blending the raw materials. In mass production, butter products are sometimes produced from individual raw materials such as milk fat, skimmed milk, buttermilk, lactic starters and other milk constituents.

The technologically achievable lower limit for butterfat content ranges between 610–620 g/kg. Special technologies must be used to produce products with lower fat percentages, and the addition of proteins, thickening agents, emulsifiers, and possibly other ingredients is necessary. In principle, any process and either cultured cream or sweet cream can be used to make butter. In order to make use of the advantages of the longer shelf life of sweet buttermilk, however, butter is increasingly made according to the NIZO process. In this process, butter produced from sweet cream is transformed into cultured-cream-flavoured butter in the final buttermaking stage using milk-based, microbially produced lactic-acid concentrates and flavour concentrates. Such a butter is either described simply as ‘butter’, or as ‘acidified butter’. The advantage of the process is that it yields sweet buttermilk, which is much easier to use than sour buttermilk, e.g. as skimmed milk, for buttermilk drinks, or for powder production.